Cheese Making

Practical Action

6. Drain the curds through cheesecloth on a mesh sieve for 20 minutes.

7. Chill and harden the curds in the cheesecloth in ice cold water for 5 minutes.

8. Mix in salt to taste and refrigerate at 4-6oC.

Semi-hard cheeses

This is a large group of cheeses and includes Edam, Gouda, Colby, Montasio, and Muenster.

Production is by rennet coagulation, and lactic acid production is restricted. The amount of

moisture removed from the curd depends on the temperature and time of cooking and by the

wash water temperature. Higher temperatures during cooking or washing cause the curd to

contract and expel more moisture. Typically, these cheeses are matured for between 2 weeks and

9 months.

Hard cheeses

Hard cheeses (e.g. Cheddar, Parmesan, Swiss, Romano) have lower moisture contents than other

types, produced by higher temperature cooking or by controlled fermentation and curd handling.

Pasta Filata types are worked and stretched in hot water and salted using brine. Cheddar types

are salted before pressing. The cheeses are ripened for 1-36 months.

The following process is used to make Cheddar cheese:

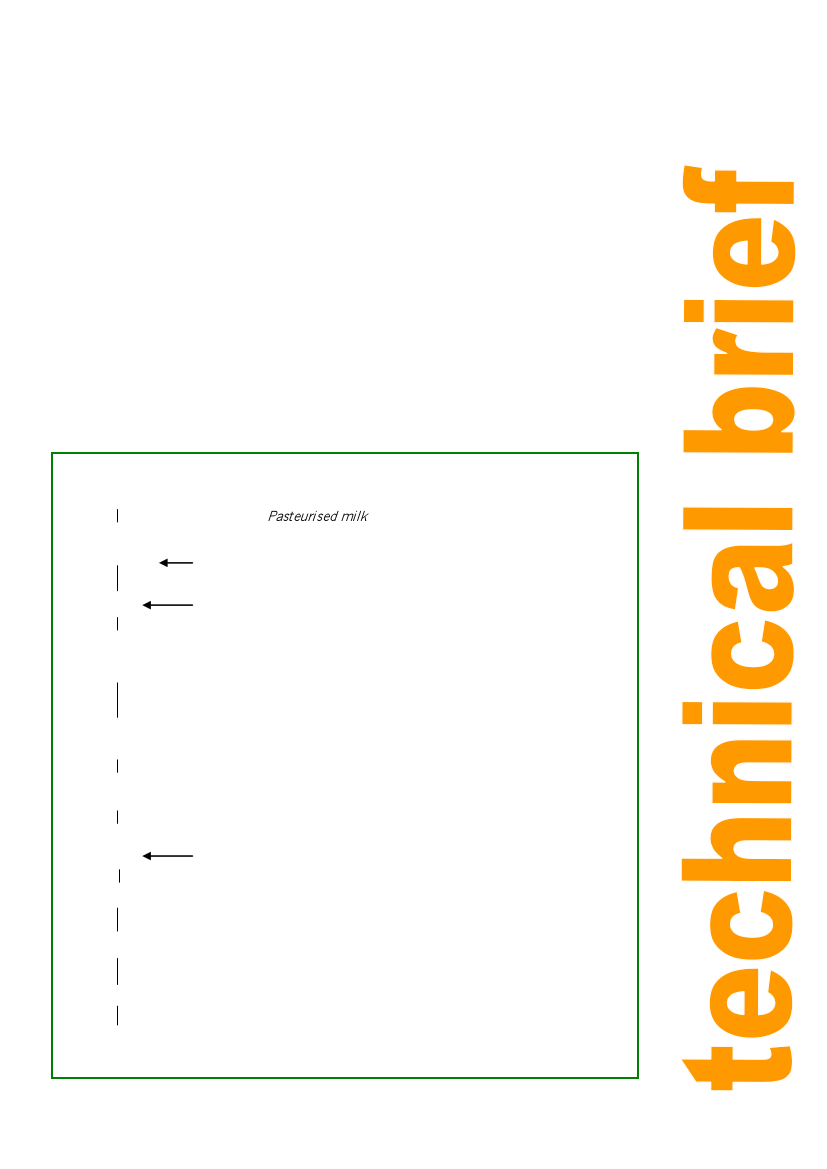

Process

Raw Milk

Pasteurise

Cool

Inoculate

Mix

Incubate

Cut

Stand

Heat

Stir/Drain

Cut

Cut

Mix

Fill

Press

Notes

Starter

culture

Rennet

Salt

Heat to 63 °C for 30 minutes (see Technical Brief:

Pasteurised milk).

Cool with stirring to 25-30°C.

Place in a stainless steel cheese vat and add 2% starter

culture for faster acid production (less for a slower

fermentation).

Mix rennet (1 tablet, 2.5 teaspoons of powder or 20 - 30 ml

liquid per 100 litres of milk) and add to the milk.

Allow milk to stand for 30 minutes until it sets to a firm

curd.

Check the curd with a spatula to determine if it is firm

enough to cut. Cut curd into 8 mm cubes, using curd

cutters (Fig. 2).

Stand for 5-10 minutes for curd to become firm.

Slowly increase the temperature by 1oC each 7.5 minutes

up to 38oC.

Stir and drain until the whey is removed.

Cut curd into blocks 150 cm thick and turn them every 15-

20 minutes.

Cut blocks into large pieces (e.g. 2-3 cm) using knives.

Add salt (approx 2% of weight of curd) and mix into the

curd pieces.

Fill the required amount of curd into a cheesecloth (which

has been boiled for 15 minutes or sterilised in dilute

bleach), and place in the cylinder of a cheese press (Fig. 4).

Apply pressure gently, allow to stand for 30 minutes and

apply more pressure. Press for 8 hours (usually overnight)

Pack

Store/ripen

Remove cheese from press, inspect, trim and pack in

cheese cloth.

Store at temperature below 15 oC, with a high air humidity

(above 85%) and mature for 3-12 months, turning the

cheese periodically.

4